Heat transfer technology is essential for creating custom apparel, promotional items, and other personalized products. Whether you’re in the garment printing business or simply looking to personalize clothing or accessories, heat transfer solutions provide a versatile and efficient way to apply designs to various materials. From traditional methods like screen printing to newer techniques such as direct-to-film (DTF) printing, there are many options to consider. Here are six key facts you need to know about heat transfer solutions.

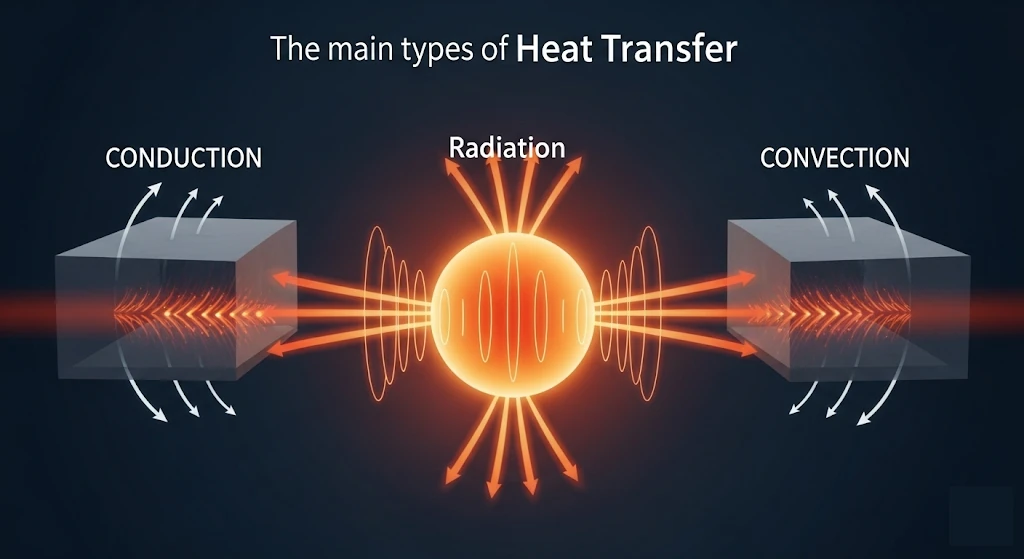

1. What Is Heat Transfer?

At its core, heat transfer involves applying heat and pressure to transfer designs onto a surface, typically fabric. The process begins with printing the design onto a special transfer paper, which is then placed on the fabric. Using a heat press machine, heat and pressure are applied, causing the design to adhere to the material permanently.

Heat transfer is commonly used in the apparel industry for creating custom T-shirts, sportswear, and promotional items. The method is known for producing vibrant, durable prints that can withstand washing and wear. The versatility of heat transfer solutions makes them suitable for various fabrics, including cotton, polyester, and blends, as well as hard surfaces like mugs or metal.

2. Different Types of Heat Transfer Methods

There are several types of heat transfer methods, each offering its own advantages depending on the project and material being used. One common method is vinyl heat transfer, which uses a cutting machine to cut designs out of heat-transfer vinyl sheets. These sheets are then pressed onto the fabric using a heat press. Vinyl heat transfer is ideal for simple, single-color designs, such as names, numbers, or logos on sports uniforms and promotional items.

Another widely used technique is screen-printed heat transfers. This method involves printing the design onto transfer paper using screen printing ink. The paper is then pressed onto the fabric, resulting in vibrant, long-lasting prints. This technique works well for large orders, as screen printing offers excellent durability and color vibrancy.

Direct to Garment (DTG) printing is another option. It works similarly to a standard inkjet printer but prints directly onto fabric, allowing for detailed, multi-color designs. However, DTG is most effective on cotton fabrics and may not be suitable for all materials.

3. The Game-Changer in Heat Transfer

A newer technology gaining popularity in the world of heat transfers is Direct to Film (DTF) transfers. Unlike DTG, which prints directly onto the fabric, DTF involves printing a design onto a special film, which is then transferred to the fabric using heat. This technique works well on a variety of fabrics, including cotton, polyester, and blends, making it more versatile than other heat transfer methods.

One of the main advantages of DTF transfers is their ability to produce high-quality, detailed prints with excellent color vibrancy. The prints are also durable and able to withstand multiple washes without fading. Because DTF transfers don’t require the fabric to be pre-treated, the process is more efficient, saving time for businesses handling large production runs. With the rise of DTF transfers, more businesses are turning to this method for its versatility and high-quality results. Whether you’re customizing T-shirts, hoodies, or other garments, DTF transfers offer a reliable, professional finish.

4. Choosing the Right Material for Heat Transfer

The type of material you choose for heat transfer projects can greatly impact the final result. Not all fabrics are created equal when it comes to heat transfer applications. For instance, cotton is one of the easiest fabrics to work with due to its ability to absorb ink and handle the heat press without issues. It’s a popular choice for custom T-shirts and casual wear.

Polyester, on the other hand, requires more care during heat transfer because it can melt or discolor if exposed to high temperatures. However, with the right settings and techniques, polyester can deliver excellent results, particularly for sportswear and athletic apparel. Blended fabrics, such as cotton-polyester mixes, are also compatible with heat transfer solutions, though some adjustments may be necessary depending on the fabric composition.

When working with heat transfer on hard surfaces, such as mugs, plates, or promotional items, materials like ceramic and metal can also be used. Specialized transfer papers and inks are required for these projects to ensure that the design adheres properly.

5. Importance of Heat Press Machines

A key element of any heat transfer project is the heat press machine. The success of your design transfer largely depends on using the right amount of heat and pressure. Heat presses come in various sizes and types, from smaller machines designed for hobbyists to larger industrial models for mass production.

It’s important to choose the correct settings for the material you’re working with. Too much heat can damage the fabric or cause the design to peel, while too little heat may not fully transfer the design. The same goes for pressure. Proper calibration of heat and pressure ensures a smooth, even transfer that will last through multiple washes or uses.

Modern heat presses come with digital controls that allow for precise temperature and timing adjustments, making it easier to achieve consistent results across different projects. Whether you’re working on small custom orders or large commercial runs, investing in a high-quality heat press machine is crucial to achieving professional-grade results.

6. Heat Transfer vs. Other Printing Methods

While heat transfer is a popular choice for customizing apparel and promotional items, it’s important to consider how it compares to other printing methods like screen printing and embroidery. Heat transfer solutions offer several advantages, including the ability to produce intricate, full-color designs with minimal setup costs. This makes it an excellent option for short-run orders or projects requiring complex designs.

Screen printing, by contrast, is better suited for large-volume orders due to its cost-effectiveness at scale. However, it requires more setup time and is less flexible when it comes to detailed, multi-color designs. Embroidery, on the other hand, offers a premium finish but may not be ideal for designs with intricate details or for use on lightweight fabrics.

Heat transfer is a versatile solution that bridges the gap between affordability, ease of use, and design flexibility, making it an ideal choice for many custom printing projects.

Heat transfer solutions offer a wide range of possibilities for creating customized apparel and promotional items. From traditional vinyl and screen-printed transfers to modern innovations, the right method depends on your project’s specific needs. Understanding how different materials, heat press machines, and transfer techniques work can help you choose the best approach for your designs. Whether you’re working on a small batch of T-shirts or a large production run, heat transfer offers an efficient, reliable, and creative way to bring your ideas to life.